영문 주메뉴

- COMPANY

- BUSINESS

- CAPABILITY

- PRODUCT

- Industrial Safety

- Construction Safety

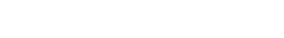

- Safety Harness and Fall

- Floor Opening Safety

- Guardrail/Scaffold Collapse

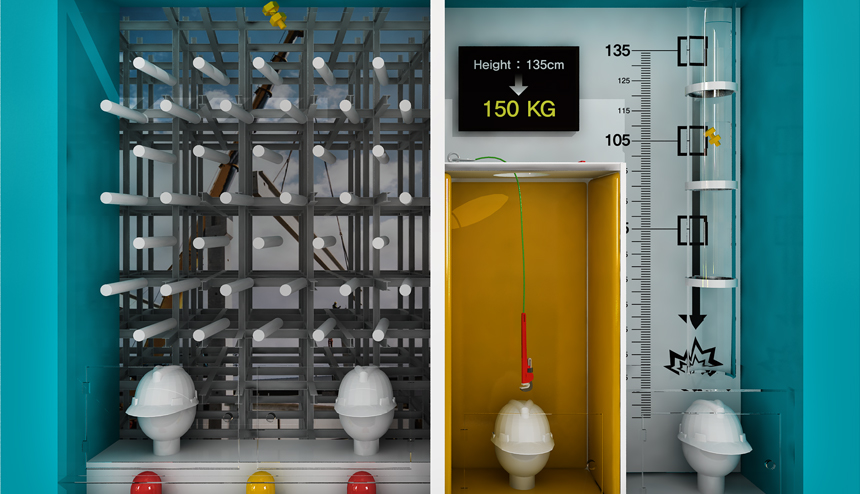

- Safety Helmet/Boots Impact

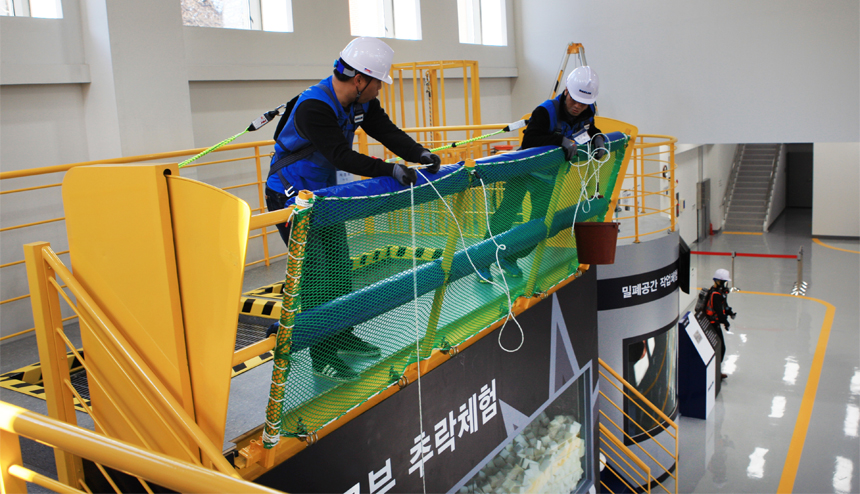

- Tunnel Safety

- Steel Structure Safety

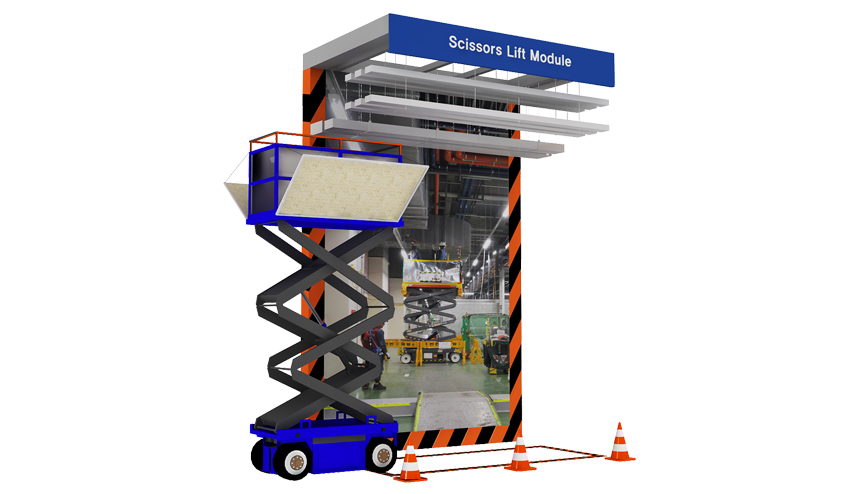

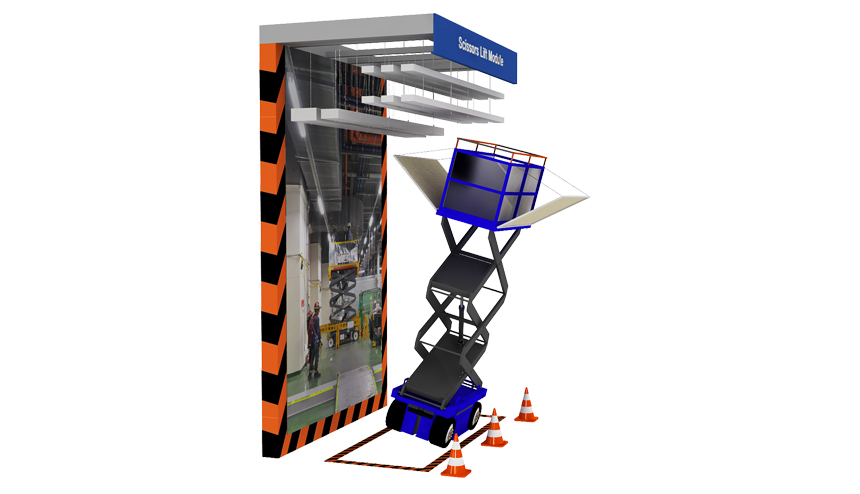

- Mobile Platform

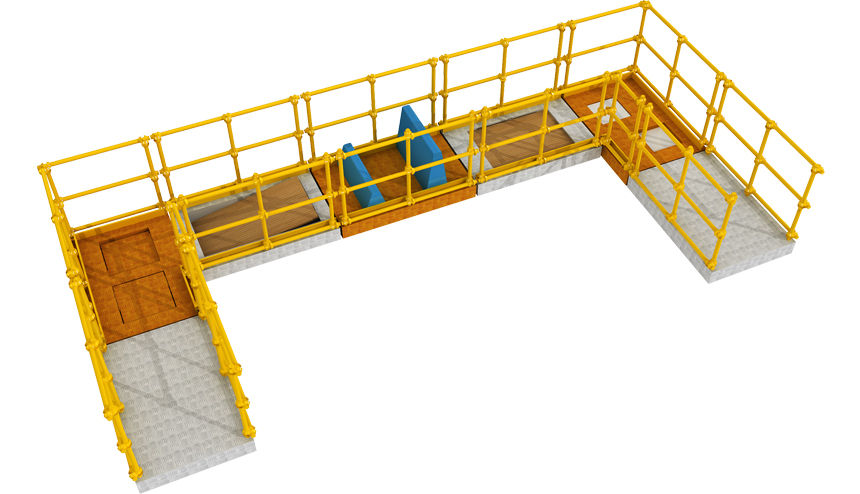

- Temporary Passage

- Vertical Ladder

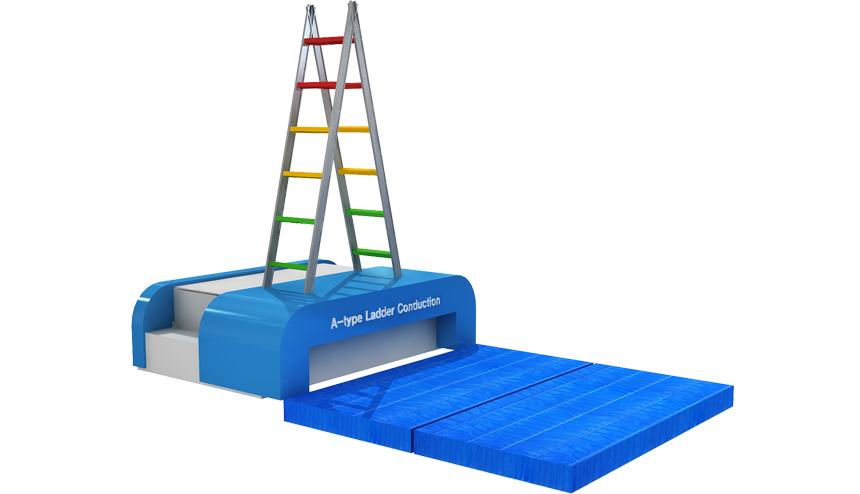

- A-Frame Ladder Collapse

- Poor Passage

- Rooftop Sliding

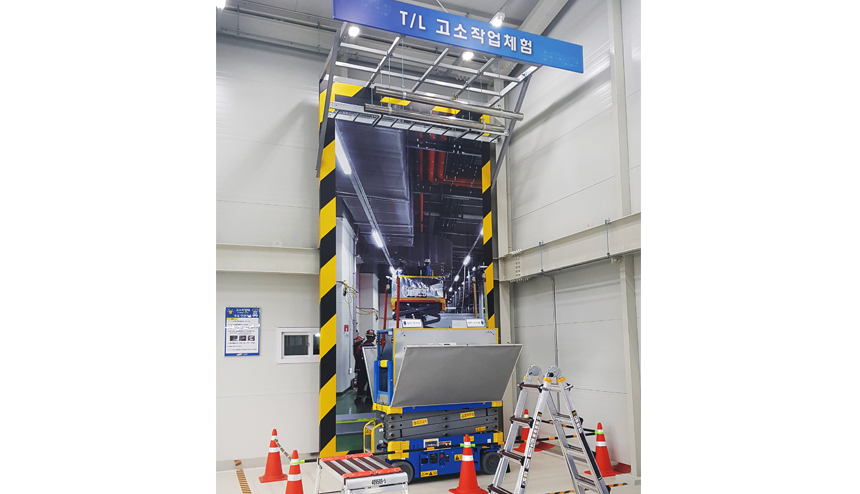

- Aerial Work

- Descending Life Line

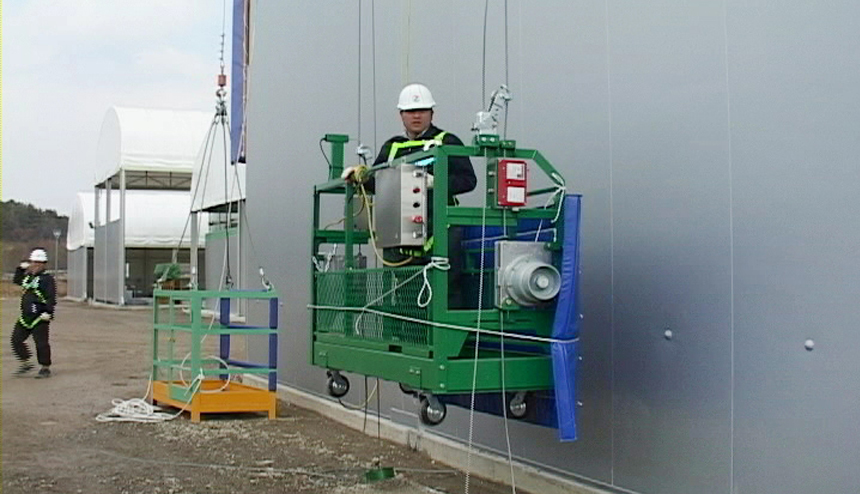

- Gondola

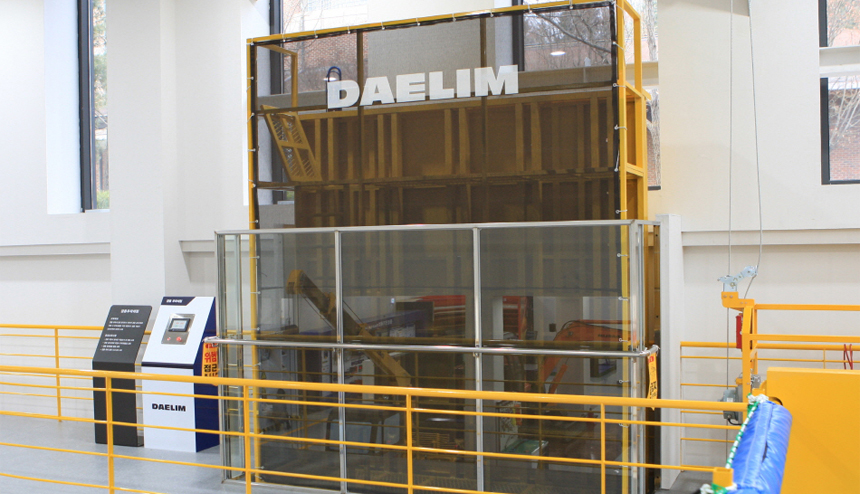

- Gang Form Fall

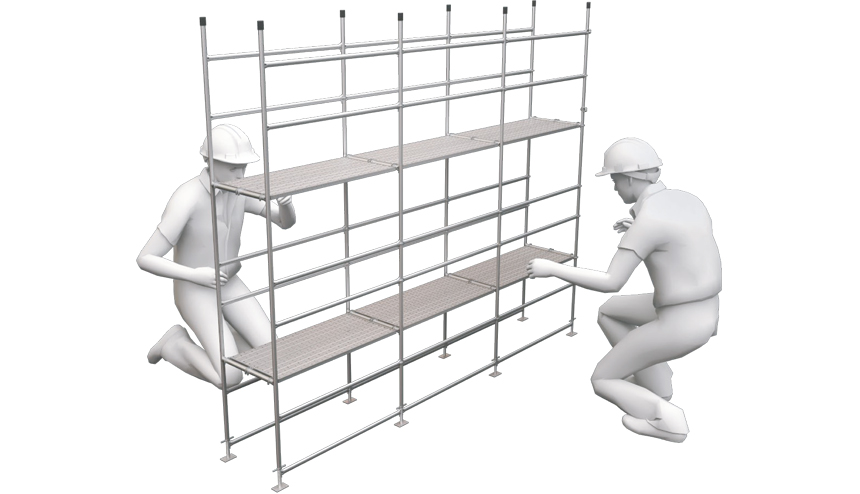

- Scaffold Safety

- Retention Wall Collapse

- Falling Objects

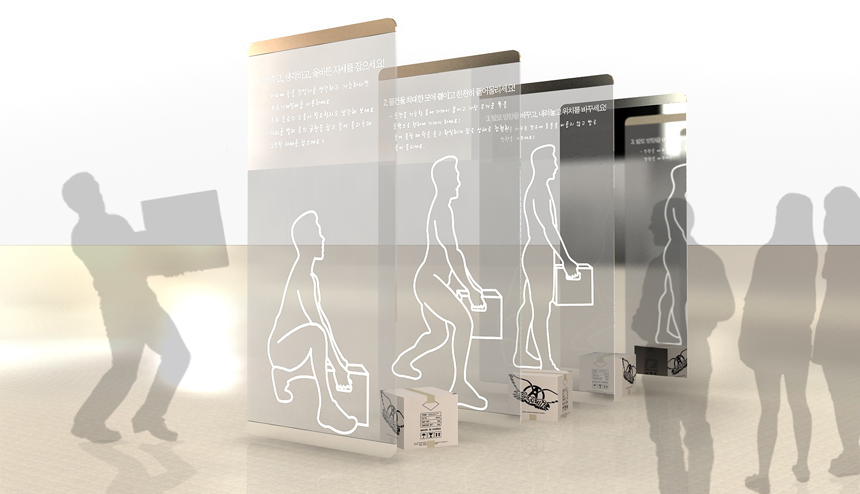

- Manual Handling

- PPE

- Machinery Safety

- Civil Safety

- VR Safety

- Movable Type

- CONSTRUCTION PERFORMANCES

- CUSTOMER